Plasma etching

Plasma etching is used to roughen a surface, on the microscopic scale. The surface of the component is etched with a reactive process gas.Material is precisely sputtered off, converted to the gas phase and pumped away via the vacuum system. The surface area is greatly increased, making the material easily wettable. Etching is used before printing, gluing and painting and is particularly useful for processing of e.g. POM and PTFE, which cannot otherwise be printed on or bonded.

Before treatment

Surface after treatment

What is plasma etching?

Plasma etching is used to make the surface of a particular material microscopically rougher. The surface is etched with a reactive process gas. Material is bombed away from the surface very precisely, converted into a gas phase and then removed via a vacuum pump. This increases the surface area and makes it easier to moisten.

What is reactive ion etching?

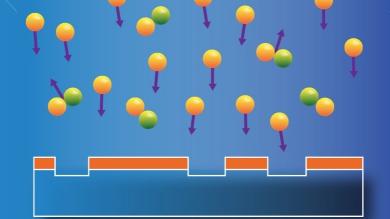

Reactive Ion Etching (RIE) provides an energetic and directed flux of reactive ions that bombard the surface. This allows a pre-marked pattern to be etched away very accurately.

Different Plasma Etching Systems

An RIE electrode can optionally be installed on all our low-pressure plasma systems. As a result, we obtain a low-cost lab system for research into semiconductors or organic electronics. Possible applications for this are:

- Treatment of materials such as POM, PTFE, FEP, PFA (can otherwise not be printed or glued);

- PTFE components;

- Applying structures in silicone;

- Etching of light-resistant layer (PCB).

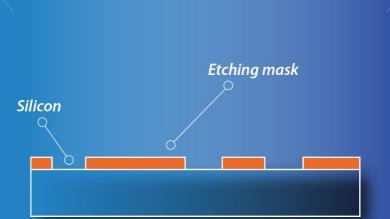

Etching mask

Plasma treatment etching

After plasma treatment

Choose the best system for your application

Discover our various plasma etching systems on offer and find the system that is best suited to your application. In addition to systems for etching, you will also find systems for other plasma treatments of different types of materials, such as Teflon or PDMS. You can rent it for a while to evaluate the technology or buy your own plasma system right away. Would you like more information or advice about your choice? Contact us via the contact form or call +32(0)478 54 69 68. We are happy to help you.